engine guide

Engine Guide: A Comprehensive Overview

Engines are vital machines converting energy into motion, powering vehicles and various applications; understanding engine types is crucial for informed choices.

What is an Engine?

An engine, fundamentally, is a machine meticulously designed to transform various forms of energy – be it chemical, thermal, or electrical – into mechanical energy. This mechanical power is then harnessed to perform work, most commonly manifesting as rotational force. At the heart of most vehicles, car engines convert fuel into the power needed to turn the wheels and propel the vehicle forward.

The scope of engines is remarkably broad, encompassing everything from the compact, fuel-efficient powerplants found in city cars to the robust, high-performance engines powering sports cars and heavy-duty trucks. They operate on principles of controlled combustion or energy conversion, and their design significantly impacts a vehicle’s performance, efficiency, and overall durability. Essentially, an engine is the driving force behind countless machines we rely on daily.

The Basic Principles of Engine Operation

Most vehicles utilize internal combustion engines (ICE), which operate by burning fuel and air within cylinders. This controlled explosion generates pressure, pushing pistons up and down – a reciprocating motion. This linear movement is then converted into rotational motion via a crankshaft, ultimately powering the wheels.

A fundamental concept is the four-stroke cycle: intake, compression, combustion (power stroke), and exhaust. Each stroke represents a piston movement, completing a full cycle. Jet engines, conversely, utilize combustion to create high-velocity exhaust for thrust. Regardless of the engine type, the core principle remains the same: converting energy into mechanical work. Understanding these basics is key to appreciating engine functionality.

Types of Internal Combustion Engines

Internal combustion engines primarily come in two forms: spark-ignition gasoline engines and compression-ignition diesel engines, each with unique characteristics.

Gasoline Engines: A Detailed Look

Gasoline engines utilize spark plugs to ignite a mixture of fuel and air within cylinders, creating controlled explosions that drive pistons. These engines are renowned for their responsiveness and relatively lightweight design, making them suitable for a wide range of vehicles. Different configurations exist, including inline and V-shaped arrangements.

Inline engines feature cylinders arranged in a single row, offering simplicity and ease of manufacturing. Conversely, V-engines, such as V6 and V8 configurations, arrange cylinders in two banks forming a “V” shape, providing a more compact footprint and enhanced power delivery. The choice between these types depends on factors like vehicle size, performance requirements, and packaging constraints. Gasoline engines remain a dominant force in the automotive industry due to their balance of performance and affordability.

Inline Engines: Characteristics and Applications

Inline engines, characterized by their straightforward design with cylinders arranged in a single row, are known for their simplicity and cost-effectiveness. This configuration minimizes internal friction, contributing to improved fuel efficiency, particularly in smaller displacement engines. They are commonly found in compact and mid-size vehicles where space constraints are less critical.

The simplicity of inline engines also translates to easier maintenance and repair. However, longer inline configurations can experience vibrations due to inherent imbalances. These engines are frequently utilized in applications prioritizing reliability and economy over ultimate power output. Their compact length makes them well-suited for front-wheel-drive vehicles, offering efficient packaging within the engine bay. They represent a foundational engine type in automotive history.

V-Engines (V6, V8, etc.): Power and Configuration

V-engines, distinguished by their cylinders arranged in two banks forming a “V” shape, offer a compelling balance of power and compactness. This configuration allows for a shorter engine length compared to inline engines with a similar cylinder count, improving vehicle packaging. Common variations include V6 and V8 engines, with higher cylinder counts generally delivering increased power output.

The V-arrangement inherently provides better engine balance, reducing vibrations and contributing to smoother operation. V8 engines, in particular, are favored in performance vehicles and trucks due to their substantial torque and horsepower capabilities. While more complex than inline engines, advancements in manufacturing have made them increasingly reliable. They represent a popular choice where a blend of power, refinement, and manageable size is desired.

Diesel Engines: Efficiency and Torque

Diesel engines are renowned for their exceptional efficiency and high torque output, making them ideal for heavy-duty applications like trucks, buses, and machinery. Unlike gasoline engines, diesel engines utilize compression-ignition, where air is compressed to a high degree, causing fuel to ignite spontaneously. This process generally results in better fuel economy compared to spark-ignition counterparts.

The higher compression ratios in diesel engines contribute to increased torque, providing substantial pulling power, especially at lower engine speeds. Modern diesel engines incorporate technologies like common rail injection to optimize fuel delivery and reduce emissions. While historically known for being noisier and producing more particulate matter, advancements have significantly mitigated these drawbacks, making them a viable and efficient power source.

How Diesel Engines Differ from Gasoline Engines

Diesel engines and gasoline engines fundamentally differ in their ignition process. Gasoline engines employ spark plugs to ignite a mixture of air and fuel, while diesel engines rely on compression-ignition. In a diesel engine, air is highly compressed, raising its temperature sufficiently to ignite the injected fuel without a spark. This leads to higher compression ratios in diesel engines.

Furthermore, diesel fuel has a higher energy density than gasoline, contributing to improved fuel efficiency. Diesel engines typically operate at lower RPMs but produce greater torque. Gasoline engines generally offer quicker acceleration and a higher power output for their size. The construction of diesel engines is often more robust to withstand the higher pressures involved in the combustion process.

Common Rail Diesel Injection: A Modern Advancement

Common rail diesel injection represents a significant leap forward in diesel engine technology. Unlike traditional systems, a common rail maintains fuel at extremely high pressure, stored in a central ‘rail’ that supplies all injectors. This allows for precise fuel metering and multiple injections per combustion cycle – pre-injection, main injection, and post-injection.

These multiple injections optimize combustion, reducing noise, emissions (particularly particulate matter and NOx), and improving fuel efficiency. The system’s electronic control enables greater flexibility and responsiveness. Common rail systems also facilitate smoother engine operation and increased power output. Modern diesel engines almost universally employ this technology, showcasing its effectiveness and widespread adoption within the automotive industry.

Alternative Engine Types

Beyond conventional designs, engines like the rotary (Wankel) and opposed-piston offer unique approaches to combustion, prioritizing efficiency and distinct performance characteristics.

Rotary Engines (Wankel Engines): Unique Design and Performance

Rotary engines, also known as Wankel engines, represent a departure from traditional piston-based designs. Instead of reciprocating pistons, they utilize a triangular rotor spinning within an oval-shaped housing. This innovative configuration delivers a remarkably smooth power delivery and a high power-to-weight ratio, contributing to exceptional performance capabilities.

The unique design minimizes vibrations and allows for higher rotational speeds. However, rotary engines historically faced challenges related to sealing the combustion chambers effectively, leading to oil consumption and emissions concerns. Despite these hurdles, their compact size and inherent simplicity continue to intrigue engineers and enthusiasts alike.

While not as prevalent as piston engines, rotary engines have found applications in automobiles (most notably Mazda vehicles) and aviation, showcasing their potential in specific niches where their distinct advantages outweigh the drawbacks.

Opposed-Piston Engines: Efficiency and Complexity

Opposed-piston engines feature two pistons within each cylinder, moving towards each other instead of a traditional piston and cylinder head arrangement. This design eliminates the cylinder head, reducing heat loss and improving thermal efficiency. The absence of a head also allows for a shorter engine, contributing to a more compact overall footprint.

However, this configuration introduces significant engineering complexities. Achieving effective sealing between the opposing pistons and the cylinder walls is a major challenge. Lubrication and scavenging exhaust gases also require intricate systems. Despite these hurdles, opposed-piston engines offer potential benefits in terms of fuel efficiency and power density.

Historically used in large diesel engines for marine and industrial applications, recent advancements are exploring their use in smaller, more efficient automotive engines, aiming to capitalize on their inherent advantages.

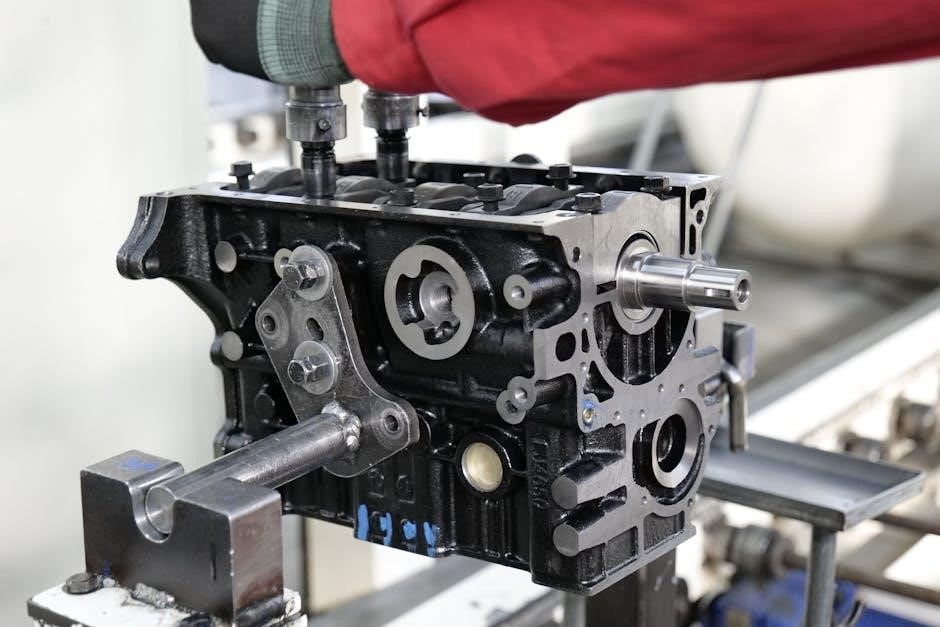

Engine Components and Systems

Engine systems, like the four-stroke cycle, cooling, and lubrication, are essential for optimal performance and longevity, ensuring efficient power conversion.

The Four-Stroke Cycle: Intake, Compression, Combustion, Exhaust

The vast majority of internal combustion engines operate on a four-stroke cycle, a fundamental principle governing their function. This cycle consists of four distinct piston strokes: intake, compression, combustion (or power), and exhaust.

During the intake stroke, the piston moves down, creating a vacuum that draws a mixture of fuel and air into the cylinder. Next, the compression stroke sees the piston move upwards, compressing this mixture, significantly increasing its temperature and preparing it for ignition.

The combustion stroke is initiated by a spark (in gasoline engines) or compression (in diesel engines), igniting the compressed mixture. This rapid expansion of gases forces the piston down, generating power. Finally, the exhaust stroke pushes the burnt gases out of the cylinder as the piston moves upwards, completing the cycle and preparing for the next intake.

This continuous repetition of these four strokes is what delivers the mechanical energy that ultimately powers a vehicle.

Engine Cooling Systems: Maintaining Optimal Temperature

Engine cooling systems are critical for maintaining optimal operating temperatures, preventing overheating and ensuring longevity. Internal combustion engines generate substantial heat during the combustion process, and without effective cooling, components could melt, warp, or seize.

Most systems utilize a liquid coolant – typically a water and antifreeze mixture – circulated through passages in the engine block and cylinder head. This coolant absorbs heat and is then pumped to a radiator, where the heat is dissipated into the atmosphere.

A thermostat regulates coolant flow, maintaining a consistent temperature. Fans, either mechanically or electrically driven, enhance airflow through the radiator. Oil cooling systems also contribute, circulating oil to remove heat from critical parts. Proper cooling prevents premature wear, maintains efficiency, and ensures reliable engine performance.

Engine Lubrication Systems: Reducing Friction and Wear

Engine lubrication systems are essential for minimizing friction between moving parts, reducing wear, and dissipating heat. Without proper lubrication, metal-to-metal contact would quickly cause significant damage. Oil, the primary lubricant, creates a protective film between surfaces like pistons, bearings, and camshafts.

A typical system includes an oil pump, which circulates oil from the oil pan through a network of passages. An oil filter removes contaminants, ensuring clean oil reaches critical components. Oil coolers help maintain optimal oil temperature, preventing breakdown and viscosity loss.

Modern systems often incorporate variable oil pumps, adjusting flow based on engine demand. Adequate lubrication extends engine life, improves efficiency, and reduces noise. Regular oil changes and filter replacements are vital for maintaining system effectiveness.

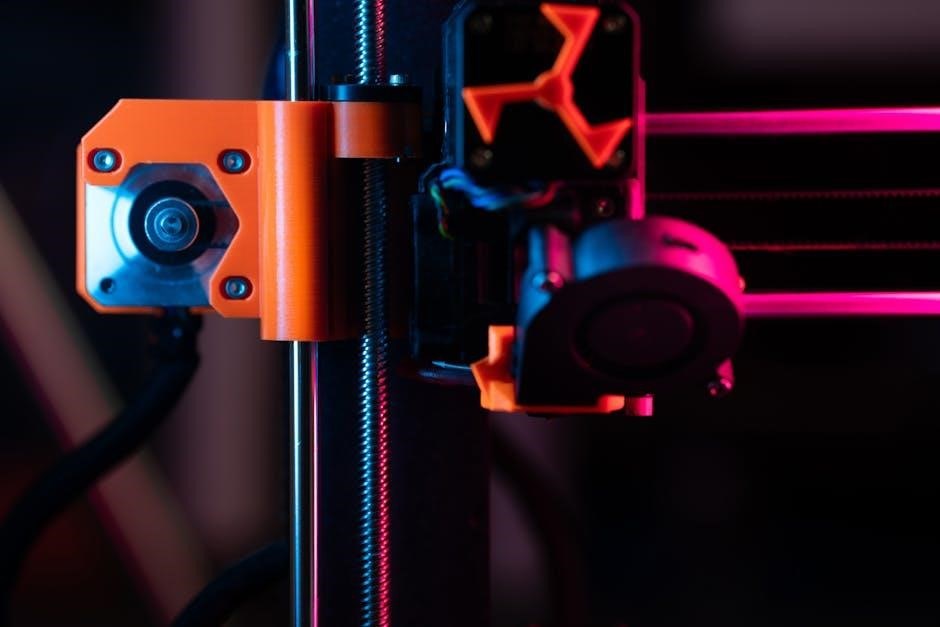

Emerging Engine Technologies

Hybrid systems blend internal combustion with electric power, while electric motors offer a shift in propulsion, reshaping the future of engines.

Hybrid Engine Systems: Combining ICE with Electric Power

Hybrid engine systems represent a significant advancement in automotive technology, strategically combining the benefits of internal combustion engines (ICE) with the efficiency of electric motors. These systems aim to reduce fuel consumption and emissions while maintaining, or even improving, performance. There are several types of hybrid architectures, including parallel, series, and power-split hybrids, each offering a unique approach to integrating the two power sources.

In a parallel hybrid, both the ICE and electric motor can directly power the wheels. Series hybrids, conversely, utilize the ICE solely to generate electricity for the electric motor, which then drives the wheels. Power-split hybrids, like those found in many Toyota Prius models, employ a more complex system allowing for a variable blend of power from both sources. Regenerative braking is a key feature of hybrids, capturing energy during deceleration and storing it in the battery for later use, further enhancing efficiency.

Electric Motors as Engines: A Shift in Propulsion

Electric motors are increasingly recognized as standalone engines, driving a fundamental shift in vehicle propulsion away from traditional internal combustion. Unlike ICEs, electric motors convert electrical energy directly into mechanical energy, offering exceptional efficiency and zero tailpipe emissions. They deliver instant torque, resulting in brisk acceleration and a responsive driving experience.

Several types of electric motors are employed in vehicles, including AC induction motors and permanent magnet synchronous motors, each with its own advantages regarding cost, performance, and efficiency. The simplicity of electric motors – fewer moving parts compared to ICEs – translates to reduced maintenance requirements and increased reliability. As battery technology continues to advance, offering greater energy density and faster charging times, electric motors are poised to become the dominant form of vehicle propulsion, reshaping the automotive landscape.